Ultraleggera is known and recognized as one of the most popular OZ wheelsThe wheel design is Formula 1 race-inspired. This article concisely covers key areas concerning aluminium alloy wheels manufacturing process Find out about alloy wheel material selection considerations and casting process options plus secondary processing methods Learn about the most popular alloy wheel composition components some of which might surprise you Aluminium alloy wheels manufacturing process have developed a.

1

Metals Free Full Text Advanced Process Simulation Of Low Pressure Die Cast A356 Aluminum Automotive Wheels Part I Process Characterization Html

Alloy Die Casting A Look At Metal Die Cast Types Of Alloys And Their Uses

After casting the gears are annealed or nomalized to remove cooling stresses.

Alloy wheel casting process. Add up to 2 tin when casting bore slugs from stick-on wheel weights to aid in mould fill out. An induction furnace is an electrical furnace where heat energy is transferred by induction and can operate with minimal melt loss. Pressures rise rapidly as charges are increased.

This very hard alloy was designed to completely fill the molds used in the printing process prior to the development of computerized typesetting in the late 20th century. Each bar measures approximately 8-34 x 1 x 2 and weighs approximately 5 lbs - 25. Obsolete cars mechanical components and similar items are separated sized and shipped to foundries as scrap.

An alloy is an admixture of metals or a metal combined with one or more other elementsFor example combining the metallic elements gold and copper produces red gold gold and silver becomes white gold and silver combined with copper produces sterling silverCombining iron with non-metallic carbon or silicon produces alloys called steel or silicon steel. Centrifugal casting is also applied to the manufacture of steel gears. The difference between the two processes is that casting involves placing liquefied aluminum into a mold.

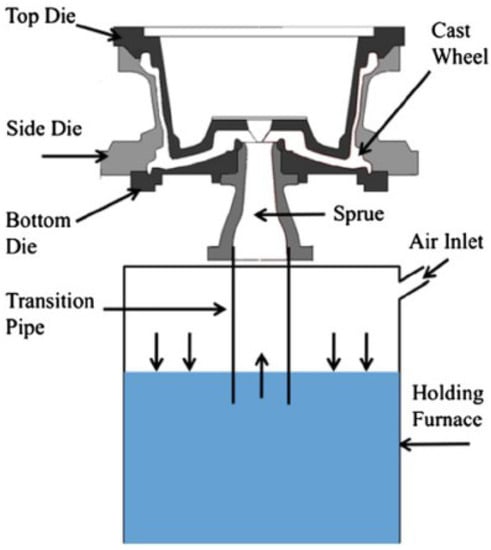

International Journal of Engineering Research Technology is a peer-reviewed open access and multidisciplinary engineering technology and science journal that publishes original research review articles of all major branches of Engineering Science and Technology. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold. There are several different ways to accomplish this including gravity casting and low-pressure casting.

Lube is injected forward during the firing process. Rally Racing the wheel that made history in rally racing is back with an even more modern and aggressive look. The timeless and genuine racing icon is reborn.

Modern steel foundries frequently utilize recycled steel scrap to reduce the cost and environmental impact of casting production. We have adopted a fully open access publishing model which allows open global access to its published content so anyone can. The investment casting of aluminium alloys results in lower strength than sand castings but offers tighter tolerances better surface finish and the capability to produce thin-walled sections.

The steelworker can also remove surface impurities de-slagging. The investment casting method also called the lost wax process is used for precision casting of aerospace components such as gas turbine blades. One was the Toyota team led by pilot Carlos Sainz who.

Future Of Automotives. Wheel weights generally have a good amount of tin in them and they usually have some antimony too. In the 90s OZ put in the best performance at the World Rally Championships where it fitted tires on the cars of some of the most important teams competing.

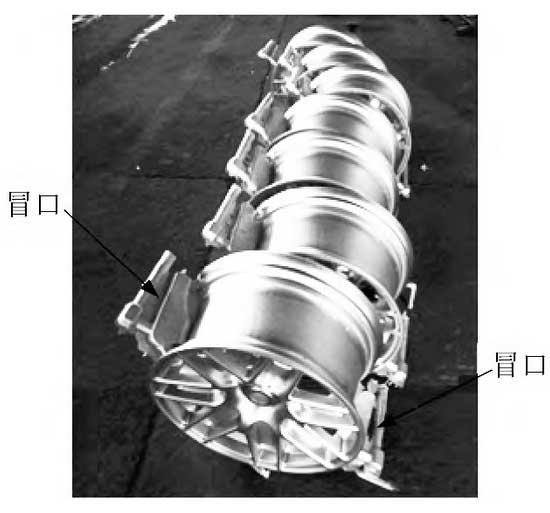

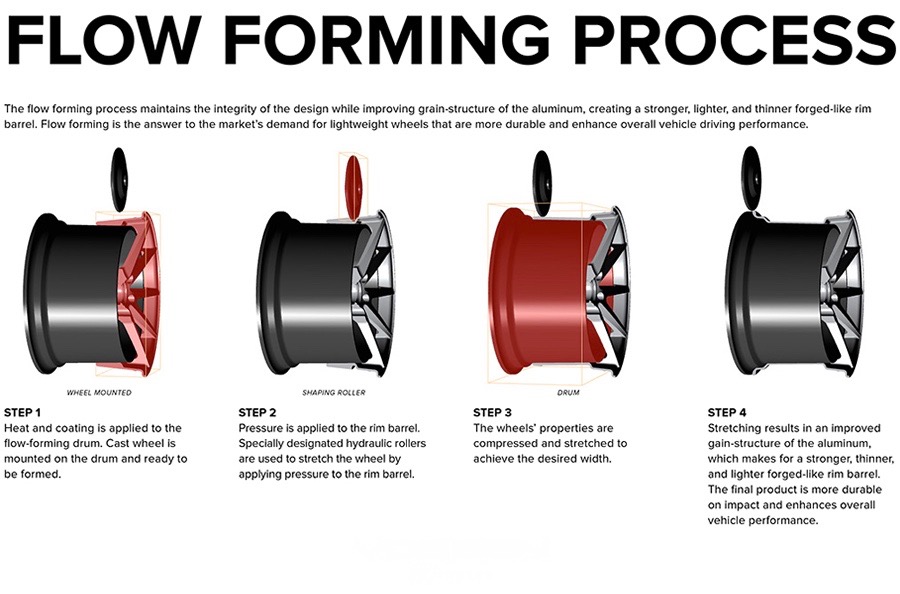

The spokes are slim and extend all the way out to the external lip the center is carved out just like on racing wheels. Iron Alloys Table 1. Most of the alloy wheels on the market are one-piece cast wheels not forged.

The difference between the two processes is that casting involves placing liquefied aluminum into a mold. After casting a batch of bullets and allowing them to cool down enough to touch do a carefulscrap alloy such as wheel weights a lot of cruddy-looking stuff will float to the molten surface. As the aluminum cools it is formed into a wheel.

For phosphor bronze worm wheel rims centrifugal casting is used far more extensively than any other method. At Rockman we have perfected the aluminium die casting process with our decade-long manufacturing experience. Casting definition the act or process of a person or thing that casts.

China aluminium alloy sand die casting DIM-273 is supplied by aluminium alloy sand die casting manufacturers producers suppliers on Global SourcesChinese foundrycustominghousing spare parts We use cookies to give you the best possible experience on our website. Whatever wheel design construction style or color you are looking for to invest in you will find it here. Composition Range for Un-Alloyed Cast Irons Iron Family Carbon Silicon Manganese Sulfur Phosphorus.

The Linotype alloy consists of 4 tin 12 antimony and 84 lead. The ladle is heated and cooled to the temperatures needed for the necessary chemical processes. Forged rims are pressed from one piece of metal while cast rims are built by pouring liquid metal into a mold.

It is a process of refining and alloying steel. Starting from a billet of 6000 series aluminum or a special magnesium alloy every BBS forged wheel uses our special multi-stage Die-Forging process which can require up to 18 million pounds of pressure to produce. Linotype and Lyman 2 alloys have the lowest hardening potential of common bullet alloys because of the higher tin content.

This gray iron manifold for wheel loaders was developed by the casting supplier and cus-tomer from concept-to-casting in less than one month. The waiting is over. Most of the alloy wheels on the market are one-piece cast wheels not forged.

200 gr bullets take up a lot of powder space in the 38 Spl case. Every stage of production is optimized to help create the best forged wheel in the industry. Elements can be added to get a specific alloy.

Alloy wheels are also purchased for cosmetic purposes although the cheaper alloys used are usually not corrosion-resistantAlloys allow the use of attractive bare-metal finishes but these need to be sealed with paint or wheel coversEven if so protected the wheels in use will eventually start to corrode after 3 to 5 years but refurbishment is now widely available at a cost. In my experience most guns will shoot straight wheel weights just fine. Melting and cleaning wheelwrights in the main casting pot keeps the pot internal surfaces dirty and stops up orifices.

In part 2 we will look in actual mixtures and a method used in the Lyman casting book that I have yet to try that makes wheel weights hard cast without adding antimony. These bullets are swcs weighing in the 170s depending on alloy. There are several different ways to accomplish this including gravity casting and low-pressure casting.

Secondary steelmaking can start by melting scrap or continues a primary process. Both vertical and horizontal axis spinners are used. This very hard alloy was designed to completely fill the molds used in the printing process prior to the development of computerized typesetting in the late 20th century.

Leading Indias two-wheeler alloy wheel manufacturing and expanding into four-wheeler alloy wheels with 125 million and 1 million yearly productions. As the aluminum cools it is formed into a wheel. Elmer Keith designed Lyman 358429 for the38 Spl.

The most well-known 6 double-spoke wheel ever. Its racing DNA is apparent in several details. The Linotype alloy consists of 4 tin 12 antimony and 84 lead.

Depending on the manufacturing process the wheels can be forged cast and pressure cast. Wider choice of material as any kind of metal alloy can be cast. The new design cut the processing time of the component in half.

Stuff like the steel clips of wheel weights can be skimmed off but be careful not to remove the stuff that looks like cruddy scum because it may be an essential-but only separated-part of the alloy.

Gravity Casting Of Aluminum Alloy Wheel Hub Zhy Casting

Alloy Wheel 101 Dezent Leichtmetallrader

The Hidden Truth Of Rotary Forged Alloy Wheels Auto Fanatic

Aluminum Alloy Wheel Rim Low Pressure Die Casting Machine Production Line

Alloy Wheel Production Line Manufacturing Equipment Application Design And Build Production Line Of Alloy Wheel

Wheel Rim

Aluminum Alloy Wheels Manufacturing Equipment Provider Taizhi

Development Of A 3 D Thermal Model Of The Low Pressure Die Cast Lpdc Process Of A356 Aluminum Alloy Wheels Sciencedirect